In my free time on weekends, I go on treks or bowling with friends. I also love to explore gadget stores like Funan and Sim Lim Square in Singapore to find out about the latest tech, sometimes I spend hours admiring the craftmanship in a digital camera or a timepiece and sometimes I just look for inspirations for personal projects.

When I am not wandering in shopping malls filled with electronics, I exploit my 3D printer to make utility tools, modification parts for my bike or something just to fix stuuf like kettle, door handles or keyboard. I buy old appliances like microwaves, tv sets and music systems and open them for fun and to explore the mechanical design inside. I observe the mechanism, internal boss extrusions, material used and much more to learn how industrial products are actually made. This greatly helps me in my personal projects as well as my job.

Few weekends are spent designing hobby projects like kirigami cards, automatic cloth hangers, robotic garment steamers etc. I take part in hardware hackathons once in a while and work on some tech projects for startups as a consultant.

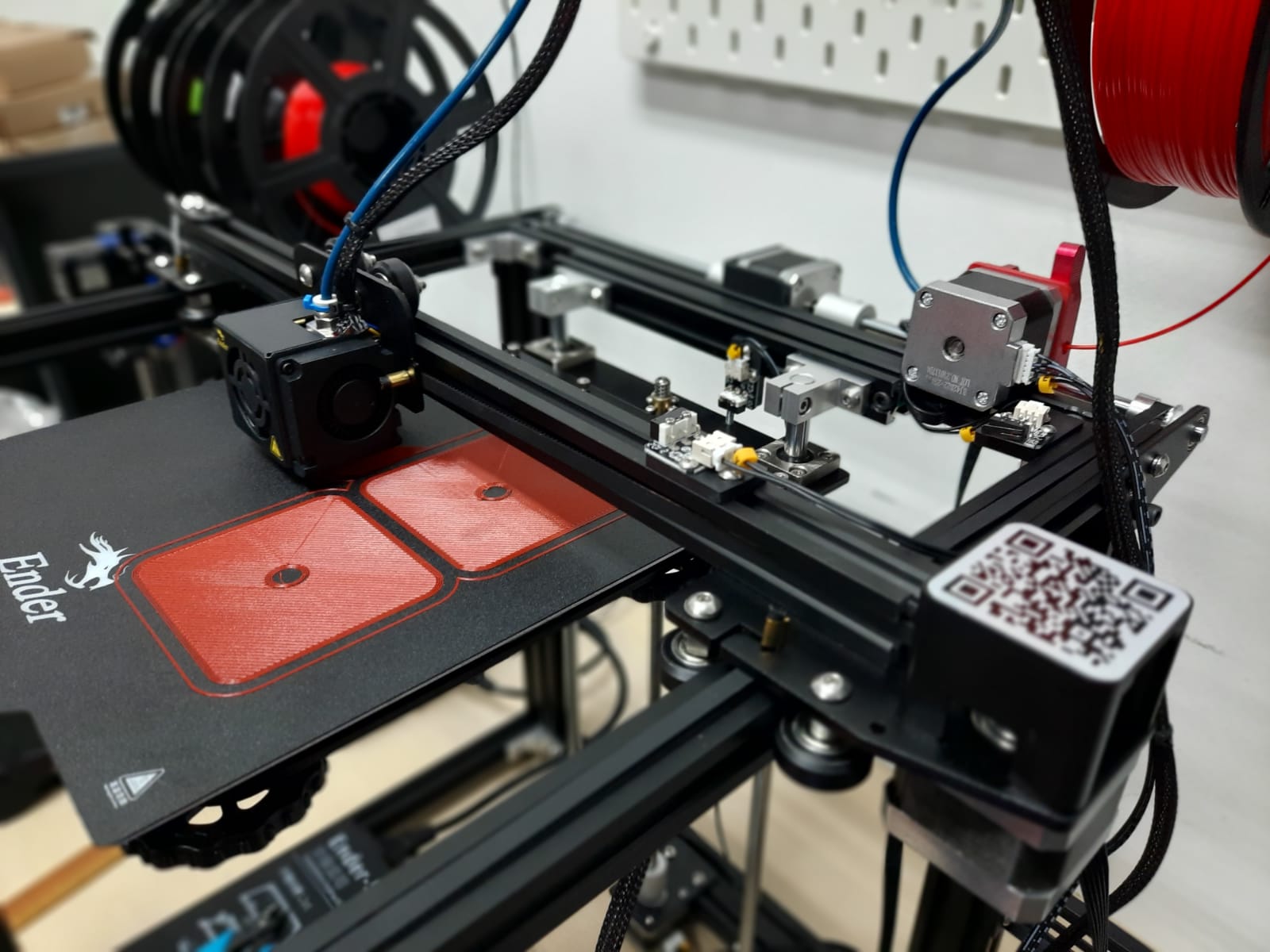

Assembling Ender 5

One of the biggest inventions for me is the 3D printer. Since college days I have worked with all kinds of 3D printers starting from little and economical prusa printers to high-end metal stratasys and metaforge printers. This is one of my timelapse videos of assembling the Ender 5 printer. Later I changed the heating bed to glossy finish board and automated the bed leveling and calibration system.

I use 3D printed prototypes to get the right idea about the size (which doesn't happen intuitively in CAD software). I use the prints also to get a feel of physical interaction and then modify the features like chamfers, fillets and undercuts to make the part more ergonomic.

.

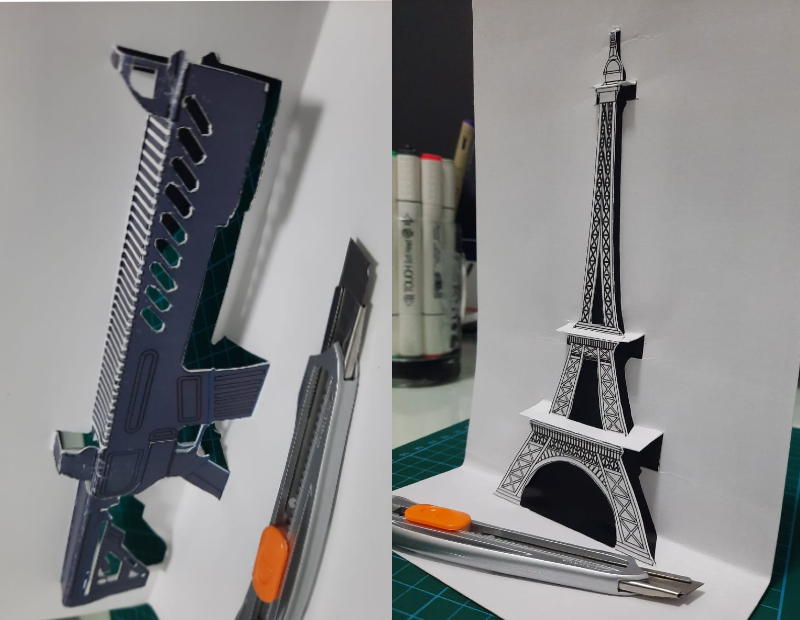

A hack to make 3D objects from paper

Kirigami is the method to create pop-out art by cutting and folding paper. However, knowing where to put the paper to create a 3D model is not very easy. Hence one gets restricted to the set of templates available online. I hacked a way into this that lets me create any physical model with Kirigami.

.

Gears and utilities

One of my hobbies is to do a tear down of toys, consumer electronics and appliances. I like to see and learn from these mechanisms, gear ratios and the arrangement in which those are stacked together. Sometimes these are part of linear drives or sometimes just a combination of a crank and a rocker.

For example, the image on the right is a gear assembly from a room freshner. The motion and torque values were similar to a strong finger press, so I used the mechanism to generate a key press on my piano to play a note every 1 hour.

The next image shows a cup holder in which the clamp had simple gear reduction to achieve a firm grip.

.

.

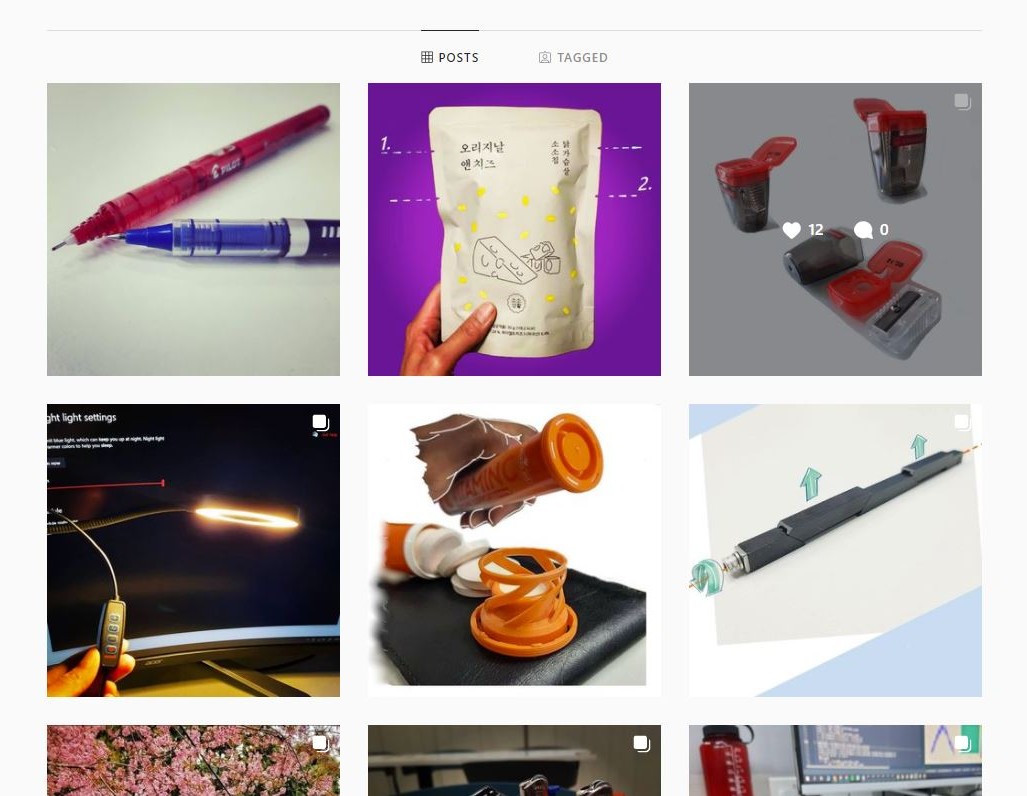

Design review

When I see things that have natural or engineered design beauty, I write a review about them on my instagram page. Link to the insta account is at the bottom of the page. For example, why does a pilot ink pen have a capillary structure in the front? or why few food packets have 4 notches for cutting instead of 2

These wonderful design features remain hidden most of the time, but after pondering for a bit one can easily point out the importance and application of these features. I get inspired by such thoughtful designs and I hope that my designs can also match these standards one day