Morphle Labs

We built robotic whole slide scanners for histopathology. Digitizing tissue slides in 400x zoom enables doctors to tele-report cases and run AI assistive diagnostics. I was responsible for designing the 3-DOF translation platform, optomechanical assembly and motion control system. I implemented many innovative ideas to make the system robust, interactive and affordable. Morphle was selected for the Y-Combinator program in 2020. Today, our scanners are deployed in 100+ labs and have taken more than 1 million scans till date.

In terms of quality, Morphle scanners compete well with scanners from Philips and Leica, still costing less than one-third of their price. The price range makes it a perfect product for the Indian market, especially for the clinics and medical institutes in tier-2 cities.

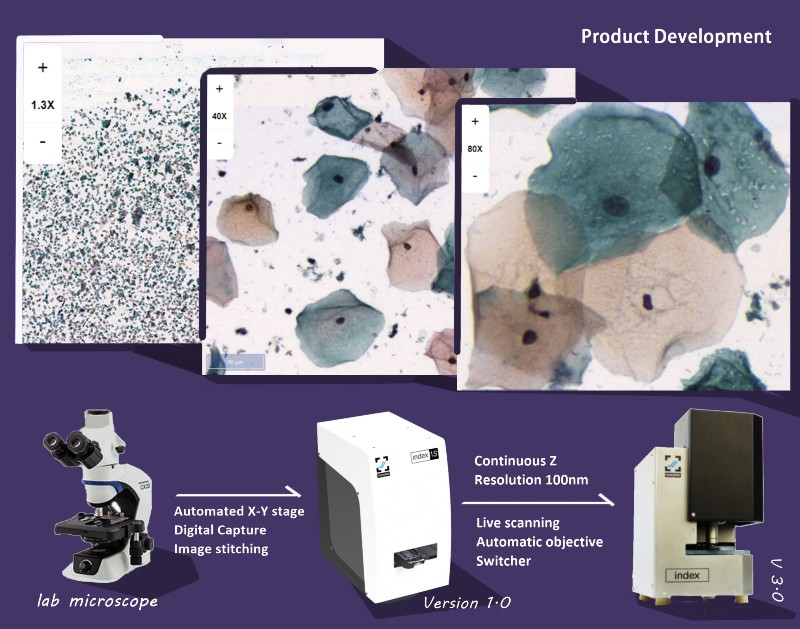

Product Development

It took 2 years of research and clever rethinking to automate a microscope and convert it into a scanner. Image on the right shows the evolution of the product. In the first step I built a translation x-y stage, controlled by GRBL firmware and driven by Nema 17 motors to move the glass slide precisely in microns. After zooming in and taking images of more than one thousand consecutive spots, the algorithm stitches them together to create a seamless scan.

The third version had a mechanism to switch between 20x and 40x objectives on the go, enabling live scanning. Time to scan was also reduced to 90 seconds. Developed shock-proof enclosure for safer international shipping.

Applications

- Digital archiving

- Z-stacking

- Localized scanning

- Changing color contrast

Engineering

The machine is a combination of lens assembly mounted on the high resolution Z-axis, glass slide mover on X-Y plane and driving electronics. I worked on the driver circuits, illumination system, fabrication and integration. I experimented with the surface finish of the glass stage to reduce friction. Compared difference between sand blasting and acid etching. Acid etching the surface solved the problem of friction and as well as diffused the light from the source, increasing the quality and brightness of the scans.

I also worked with the 4MP preview imaging system that helped the doctors see the orientation of the slide and helped the software to calibrate the coordinates of tissue samples. I handled end to end manufacturing and quality controls of all aluminum, brass and steel components. I also enjoyed going to hospitals and medical colleges in India for product demos. I have realised that talking directly to the end user is always most insightful for any engineer. I visited more than 20 institutions all across India during the year 2019. 15 out of those 20 are using our scanners today.

Demonstration

This video shows how live microscopy works. This recent feature makes the user experience much more intuitive and similar to using a physical microscope.

Insert the slide - skim through it - zoom into the desired field - inspect - report.

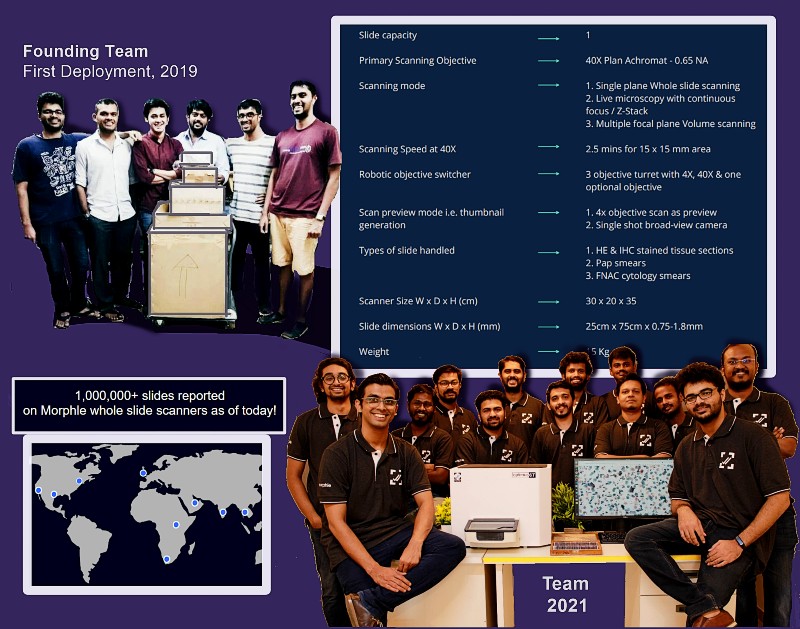

Team

In late 2018, when I joined morphle labs, we were a group of 5 engineers from mechanical and electronics and computer science background. Although we were completely new to the domain of pathology, we were aware of the state of healthcare system in India and wanted to build best class products in a low scale budget.

I love working in a small team because I get to see a bigger picture of what is happening. It gave me an opportunity to learn from everyone else and admire the intricacies of their work. Understanding other subsystems and their possible interaction with mine, helped me to design better solutions. As a part of a small startup, I had to handle multiple other responsibilities that made me better at programming, communication and management.

Currently Morphle has over 30 people in the team and scanners deployed in 8 different countries. This is a great achievement for the team and I am glad that I got the opportunity to be a part of it.